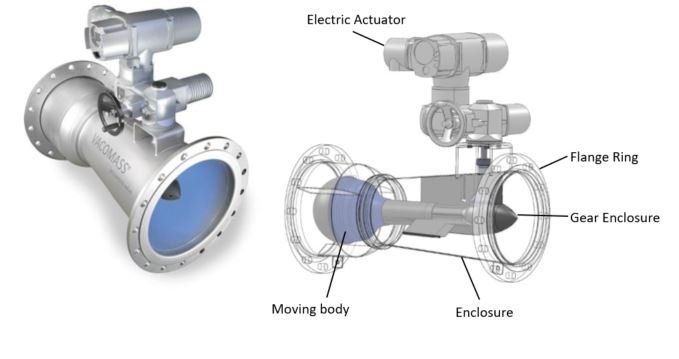

VACOMASS® Flow Meters

The VACOMASS® Flow Meters are for measuring the flow rate of aeration air in wastewater treatment plants up to 220°C.

Features of VACOMASS® Flow Meters

1) Thermal dispersion air mass flow meter

2) Direct measurement of normal volumetric or gas mass flow in dry gases at standard conditions

3) Flow measurements unaffected by pressure and temperature fluctuations

4) Stainless-steel sensor with no moving parts

5) Compact and rugged design for good reliability, maintenance-free, corrosion-proof

6) Easy installation and servicing

7) Dynamic response ideal for monitoring, totalisation and control

8) 10-digit LED display to indicate actual flowrate or totalised flow

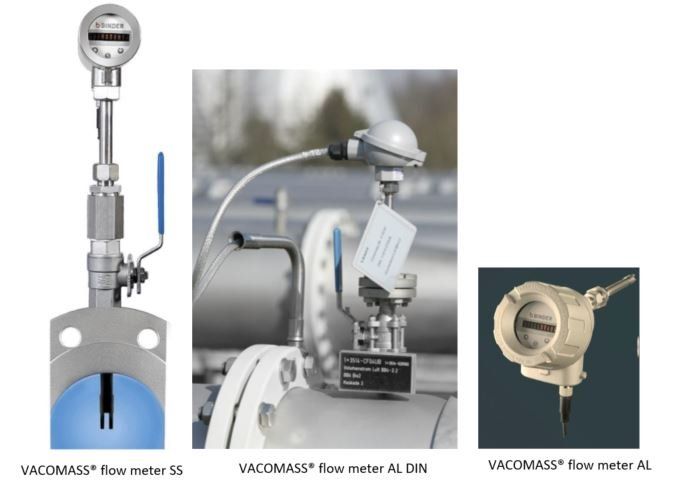

Different Models of VACOMASS® Flow Meters

1) VACOMASS® flow meter SS

a. Electronics are located in a compact, pressure-rated stainless-steel body with a sealed connector box. 10-digit LED integrated display is an

option

2) VACOMASS® flow meter AL

a. Electronics are located in a compact aluminium body. 10-digit LED integrated display is an option

3) VACOMASS® flow meter AL DIN

a. Electronics are located in a compact aluminium body

4) VACOMASS® flow meter AL 100

a. Electronics are located in a compact aluminium body. 10-digit LED integrated display is an option. The unit has an analog input for the position signal from the control valve, to allow correction of the raw flow signal to achieve an accurate flow measurement

5) VACOMASS® flow meter Multi

a. A multiple sensor flow meter for large diameter pipes

6) VACOMASS® OEIN-S

a. Hot taping unit with manual ball valve and variable insertion depth

7) VACOMASS® OEIN-F

a. Hot taping unit with manual ball valve, fixed sensor insertion depth and fixed sensor orientation